Equipment

- Other Services

New Arrivals

-

Manual Deoiling & Dewatering Machine

Manual Deoiling & Dewatering Machine

₦510,000.00Original price was: ₦510,000.00.₦470,000.00Current price is: ₦470,000.00. -

Manual Deoiling | Dewatering Machine

Manual Deoiling | Dewatering Machine

₦390,000.00Original price was: ₦390,000.00.₦320,000.00Current price is: ₦320,000.00. -

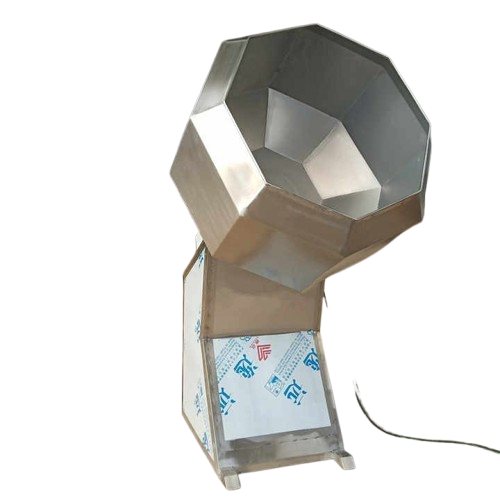

Manual Peanut Roasting Machine

Manual Peanut Roasting Machine

₦450,000.00Original price was: ₦450,000.00.₦320,000.00Current price is: ₦320,000.00. -

Coated Peanut Deep Fryer (Electrical)

Coated Peanut Deep Fryer (Electrical)

₦850,000.00Original price was: ₦850,000.00.₦820,000.00Current price is: ₦820,000.00. -

Cashew Nut Cracking Machine - 6-Way Knives

Cashew Nut Cracking Machine - 6-Way Knives

₦5,600,000.00Original price was: ₦5,600,000.00.₦5,200,000.00Current price is: ₦5,200,000.00.

Most Popular

-

Plantain Chips eBook

₦6,500.00

Plantain Chips eBook

₦6,500.00

-

Plantain Chips eBook (Free Copy)

Rated 4.50 out of 5₦0.00

Plantain Chips eBook (Free Copy)

Rated 4.50 out of 5₦0.00 -

Complete Deep Fryer Gas Operated

Complete Deep Fryer Gas Operated

₦370,000.00Original price was: ₦370,000.00.₦350,000.00Current price is: ₦350,000.00. -

Round Stainless Basket for Deep Fryer

₦80,000.00

Round Stainless Basket for Deep Fryer

₦80,000.00

-

Deep fryer tank

₦120,000.00

Deep fryer tank

₦120,000.00

-

- Chips ProductsComing soon

All products

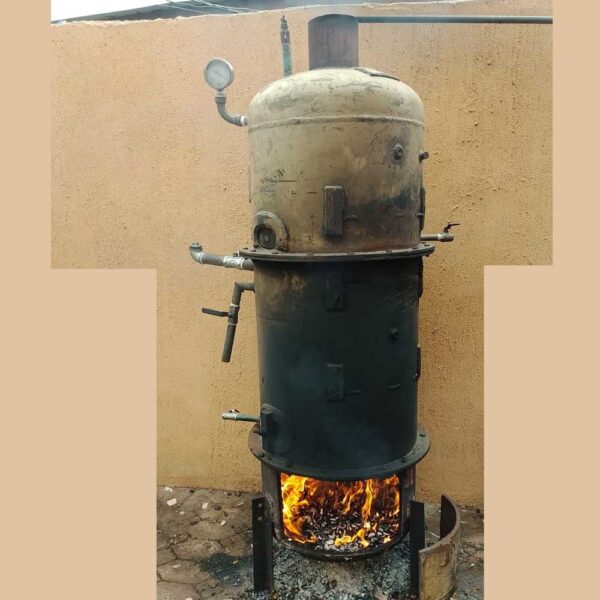

Setting up cashew for peeling the inner back often called testa, takes about two processes. The first one is oven dry gently at 60 degree centigrade for about 8 – 16 hours before subjecting it to humidification chamber. Humidification is the process of passing hot air (steam) on the cracked cashew. Cold water can also be used.

This will prevent the cashew from becoming too brittle. Steam helps facilitate the peeling but can sometimes affect the cashew’s colour if not done properly.

Our humidifying chamber help to ensure even spread of hot steam from the steam engine to all the parts of the cashew nut.

Plantain Chips

Plantain Chips